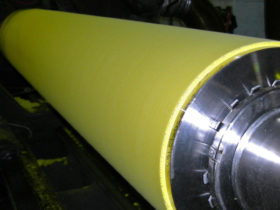

With a higher coefficient of friction than rubber, urethane or carbide coated rolls, 3M™ Mill Rolls can increase tension levels for improved line control and the resulting output quality. Compared to rubber, for example, independent testing shows that tension can be of magnitudes greater. Greater coefficient of friction can provide the following benefits:

-

Faster line speed with less slippage

-

Fewer defects related to slippage

-

Minimized sag or catenary

-

Better line control

-

Straighter edge registry

-

Reduced droop and movement in annealing furnaces

Being low maintenance while having a relatively long and consistent operational life has also been identified as a major value basis for users of 3M™ Mill Rolls as tension rolls and bridle rolls, in particular.