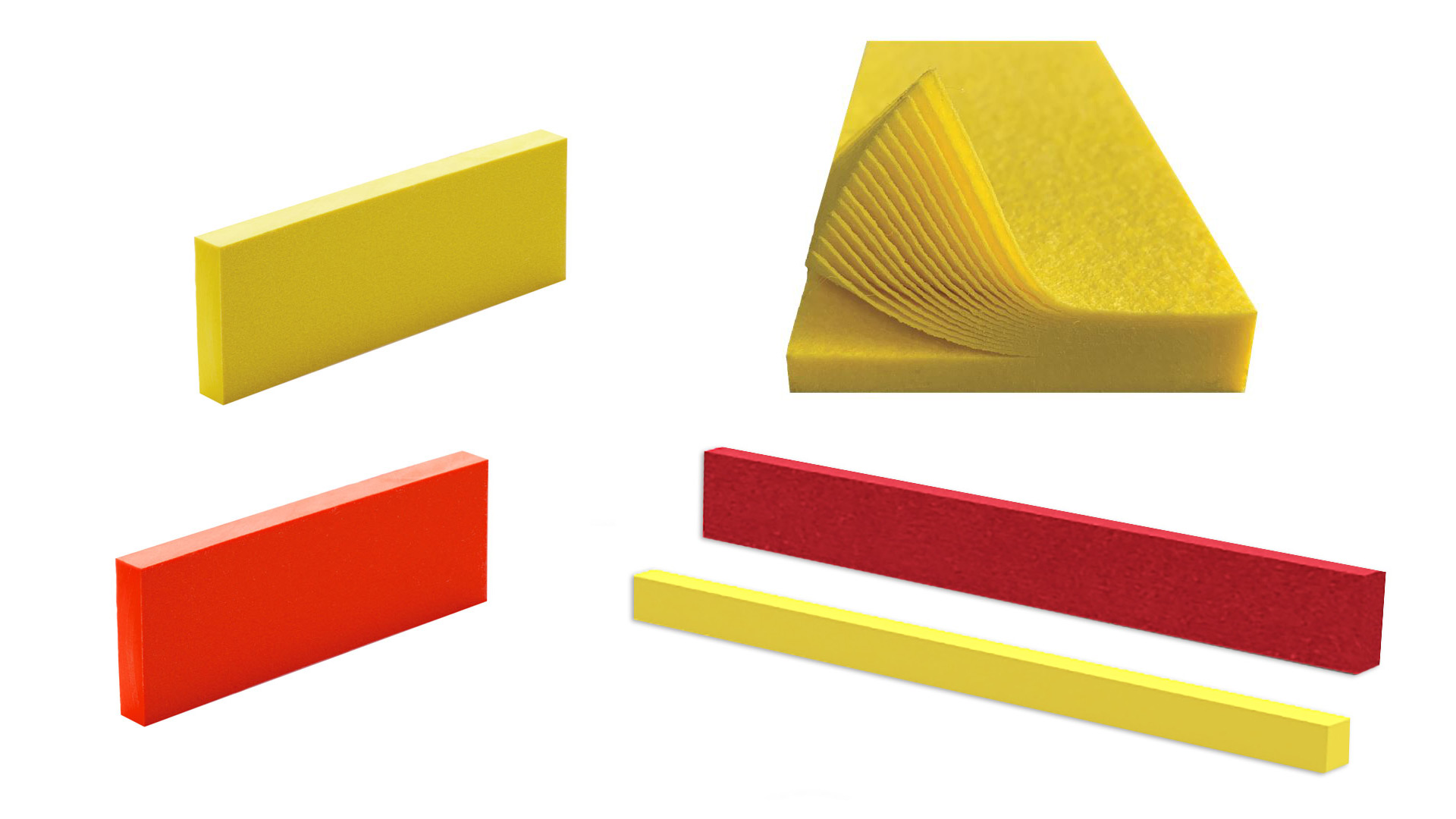

3M™ Wipe products last longer and work better than felt, rubber, and other traditional wipe materials. 3M™ brand Wipes are made from a unitized matrix of strong, synthetic fibers and resilient resin systems. Premium non-woven webs are produced and then laminated to form tough sheets and blocks that can be utilized for many tasks in a primary metal production plant.

The unique construction provides many performance advantages:

-

Utilizes porosity of non-woven web to absorb oxides from rolls and hydrostatic force of moving fluids..

-

Resists tearing by sharp, ragged edges on metal strip.

-

Resists gouging, chunking, or fraying despite exposure to rough surfaces and coil splices.

-

Maintains a uniform and even edge that controls fluids and debris long after conventional products fail.

-

Able to maintain high resiliency and compressibility so that it can follow typical changes in surface topography with consistent & firm pressure.

-

Dimensionally stable compared to traditional wipe products that allows for firm fixturing.

Some common and successful applications are these

Remove and absorb debris and oxides

Rolling Mill Roll Wipes

Bridle Roll Wipes

Conductor Roll Wipes

Line tension pads

Near exit / entry shears

Simple drag pads

Basic fluid control wipes

Applying oils to the surface

Removing fluids from the surface

Non-Marking pad surfaces for critical/high-value product

Hoist and truck pads

Floor pads for coil storage

3M™ Brand Wipe products can help significantly improve operations and applications where traditional wipe products are used and/or where there is insufficient space or funds for cleaning rolls to be utilized.